Graphene Production Technologies Market to Hit USD 970.9 Million by 2034, Driven by Scalable Manufacturing Innovations

Advancements in CVD, LPE, and plasma methods drive scalable, cost-effective graphene production for diverse high-performance applications.

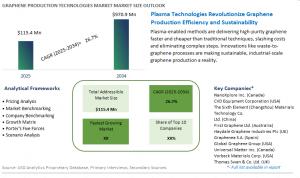

HYDERABAD, TELENGANA, INDIA, July 16, 2025 /EINPresswire.com/ -- July 16, 2025 — The global Graphene Production Technologies Market is set for exceptional growth, forecast to expand from USD 115.4 million in 2025 to an impressive USD 970.9 million by 2034, registering a robust CAGR of 26.7% during the period. According to insights from USDAnalytics, this surge is fueled by groundbreaking advances in Chemical Vapor Deposition (CVD), Liquid-Phase Exfoliation (LPE), electrochemical techniques, and plasma processes, enabling scalable, cost-effective production of high-quality graphene to meet the surging demand across electronics, energy storage, composites, and advanced materials industries.

Graphene Production Technologies Propel Industrial-Scale Adoption

Graphene’s exceptional properties—electrical conductivity, mechanical strength, thermal stability, and atomic thinness—have long promised to transform multiple industries. However, scalable and cost-effective production has been the key bottleneck preventing widespread commercialization.

Innovations in graphene production technologies are now bridging this gap. CVD techniques deliver high-purity monolayer and few-layer graphene sheets for electronics and photonics applications, offering unmatched quality for transparent conductors, flexible displays, and high-frequency devices. Liquid-Phase Exfoliation (LPE) and mechanical exfoliation methods are proving vital for producing bulk quantities of graphene nanoplatelets (GNPs), graphene powders, and dispersions used in composites, coatings, and energy storage materials.

Meanwhile, electrochemical exfoliation and plasma-based methods are emerging as disruptive technologies, delivering scalable, eco-friendly, and cost-effective pathways to produce functionalized graphene derivatives such as graphene oxide (GO), reduced graphene oxide (rGO), and graphene quantum dots (GQDs). These advances are crucial for industries demanding graphene at industrial volumes with consistent quality and performance.

Download a free sample here: Graphene Production Technologies Market Sample

Segmentation Highlights Diverse Technological Pathways

USDAnalytics’ comprehensive market analysis underscores dynamic opportunities across multiple production methods and end applications:

• By Technology:

o Chemical Vapor Deposition (CVD): Leading the market for high-purity graphene sheets and films for electronics and photonics.

o Mechanical Exfoliation: Remaining relevant for research-grade materials and proof-of-concept developments.

o Liquid-Phase Exfoliation (LPE): Gaining momentum for scalable production of graphene nanoplatelets and powders for industrial composites and coatings.

o Electrochemical Exfoliation: Emerging as an eco-friendly, scalable method producing high-quality functionalized graphene.

o Reduction of Graphene Oxide (rGO): Offering cost-effective routes to industrial graphene for coatings, composites, and conductive inks.

o Plasma Methods & Others: Innovating unique production processes that balance quality, cost, and scalability.

• By End Product Form:

o Graphene Sheets/Films: Targeting high-end electronics, transparent conductive films, and flexible devices.

o Graphene Nanoplatelets (GNPs): Dominating applications in composites, thermal management, and coatings.

o Graphene Oxide (GO) and Reduced GO: Essential for functionalized materials in sensors, membranes, and biomedical applications.

o Graphene Powder/Flakes and GQDs: Opening avenues in energy storage, catalysis, and photonics.

• By Application:

o Electronics & Photonics: Leading adoption for transparent conductors, flexible electronics, and high-frequency devices.

o Energy Storage: Integrating graphene for enhanced batteries, supercapacitors, and fuel cell components.

o Composites: Gaining momentum for lightweight, high-strength materials in automotive, aerospace, and construction sectors.

o Coatings: Employing graphene for corrosion resistance, thermal management, and EMI shielding solutions.

o Others: Including sensors, biomedical devices, filtration membranes, and advanced industrial products.

• By Scale of Production:

o Research & Lab Scale: Maintaining importance for material innovation and proof-of-concept prototypes.

o Pilot Scale: Bridging laboratory breakthroughs to pre-commercial production volumes.

o Industrial/Commercial Scale: Rapidly growing to supply mass-market applications and industrial integration.

• By End-Product Quality:

o High-Purity / Research Grade Graphene: Serving electronics, photonics, and specialized research markets.

o Industrial Grade Graphene: Dominating bulk applications requiring consistent performance and cost-effectiveness.

o Functionalized Graphene: Tailored for specific applications demanding unique chemical or physical properties.

Asia-Pacific Dominates Global Production Capacity

Asia-Pacific remains the world’s epicenter of graphene production, led by China’s significant investments in manufacturing infrastructure and process innovation. Chinese producers are scaling LPE and chemical reduction processes to supply vast volumes of graphene nanoplatelets, GO, and rGO for domestic and global markets. South Korea and Japan are advancing CVD and precision manufacturing techniques for electronics-grade graphene, powering developments in flexible displays, high-speed devices, and next-generation sensors.

North America, especially the United States and Canada, is forging ahead in scalable graphene production with strong emphasis on eco-friendly processes, high-purity materials, and commercial partnerships. Innovators are targeting energy storage, composites, and electronic applications with advanced production solutions bridging cost and performance.

Europe is emerging as a hub for sustainable graphene production, driven by the EU’s regulatory focus on green manufacturing and materials innovation. Countries like the UK, Germany, Spain, and Italy are investing heavily in commercializing graphene technologies, emphasizing functionalized graphene materials, scalable CVD systems, and advanced composite integrations. European manufacturers are also prioritizing closed-loop processes and environmental compliance to meet ambitious sustainability goals.

Competitive Landscape: Industry Leaders Drive Scale-Up and Innovation

The graphene production technologies market is defined by a vibrant mix of pioneering innovators, established manufacturers, and strategic partnerships. Leading players include:

• NanoXplore Inc. (Canada)

• CVD Equipment Corporation (USA)

• The Sixth Element (Changzhou) Materials Technology Co., Ltd. (China)

• First Graphene Ltd. (Australia)

• Haydale Graphene Industries Plc (UK)

• Graphenea S.A. (Spain)

• Global Graphene Group (USA)

• Universal Matter Inc. (Canada)

• Vorbeck Materials Corp. (USA)

• Thomas Swan & Co. Ltd. (UK)

• Directa Plus S.p.A (Italy)

• Graphene Manufacturing Group (Australia)

• Versarien Plc (UK)

• 2D Carbon Graphene Material (China)

These companies are deploying diverse competitive strategies, ranging from proprietary production processes and cost optimization to partnerships with electronics giants, automotive OEMs, and energy companies. NanoXplore Inc. is scaling up production of graphene powders for industrial composites, while Graphenea S.A. focuses on high-purity CVD graphene sheets for electronics and photonics markets. First Graphene Ltd. and Haydale Graphene Industries Plc are pioneering functionalized graphene materials tailored for advanced composites and coatings, driving commercial adoption across multiple industries.

Strategic collaborations and technological innovations are intensifying as market players race to meet global demand for scalable, high-quality, and cost-effective graphene solutions.

Future Outlook: Graphene Production Technologies Power Next Industrial Revolution

The future of the Graphene Production Technologies Market is anchored in the industry’s ability to deliver scalable, affordable, and application-specific graphene materials for diverse markets. As industries increasingly demand lighter, stronger, and more efficient materials, breakthroughs in production methods will unlock graphene’s transformative potential across electronics, energy, composites, and beyond.

USDAnalytics forecasts that continued advancements in production technology, declining costs, and expanding industrial partnerships will propel graphene from specialized material to mainstream industrial cornerstone, revolutionizing manufacturing and enabling unprecedented product innovations in the coming decade.

For full access to the complete report with in-depth data and forecasts, visit: Graphene Production Technologies Market Report, 2025–2034

About USDAnalytics

USDAnalytics is a leading market intelligence and consulting firm specializing in advanced materials, manufacturing technologies, and emerging markets. With proprietary research methodologies and global expert networks, USDAnalytics delivers actionable insights that help businesses navigate disruptive technologies and seize transformative growth opportunities.

Harry James

USD Analytics

+ +1 213-510-3499

harry|usdanalytics.com| |harry|usdanalytics.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Cellular Health Supplement Market Reach USD 3,668.1 Million by 2035 as Demand for Anti-Aging & Immunity Support Surges

Autonomous Robots Market to Reach USD 34.64 Billion by 2035, Powered by Healthcare and Logistics Demand

Synthetic Zeolites Market | Industry Insights 2031: Demand Trends & Global Expansion

Więcej ważnych informacji

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Farmacja

Nowy pakiet farmaceutyczny ma wyrównać szanse pacjentów w całej Unii. W Polsce na niektóre leki czeka się ponad dwa lata dłużej niż w Niemczech

Jeszcze pod przewodnictwem Polski Rada UE uzgodniła stanowisko w sprawie pakietu farmaceutycznego – największej reformy prawa lekowego od 20 lat. Ma on skrócić różnice w dostępie do terapii między krajami członkowskimi, które dziś sięgają nawet dwóch–trzech lat. W Unii Europejskiej wciąż brakuje terapii na ponad 6 tys. chorób rzadkich, a niedobory obejmują również leki ratujące życie. Nowe przepisy mają zapewnić szybszy dostęp do leków, wzmocnić konkurencyjność branży oraz zabezpieczyć dostawy.

Handel

Wzrost wydobycia ropy naftowej nie wpłynie na spadek cen surowca. Kierowcy jesienią zapłacą więcej za olej napędowy

Sierpień jest trzecim z rzędu miesiącem, gdy osiem krajów OPEC+ zwiększa podaż ropy naftowej na globalnym rynku; we wrześniu nastąpi kolejna zwyżka. Kraje OPEC, zwłaszcza Arabia Saudyjska, chcą w ten sposób odzyskać udziały w rynku utracone na skutek zmniejszenia wydobycia od 2022 roku, głównie na rzecz amerykańskich producentów. Nie należy się jednak spodziewać spadku cen ropy, gdyż popyt powinien być wysoki, a pod znakiem zapytania stoi dostępność ropy z Rosji. Nie zmienia to faktu, że jesienią ceny paliw na stacjach zazwyczaj rosną, a w największym stopniu podwyżki dotyczyć będą diesla.

Nauka

Szacowanie rzeczywistej liczby użytkowników miast dużym wyzwaniem. Statystycy wykorzystują dane z nowoczesnych źródeł

Różnica między liczbą rezydentów a rzeczywistą liczbą osób codziennie przebywających w Warszawie może sięgać nawet niemal pół miliona. Rozbieżności są dostrzegalne przede wszystkim w dużych miastach i ich obszarach funkcjonalnych. Precyzyjne dane populacyjne są tymczasem niezbędne w kształtowaniu usług społecznych i zdrowotnych, edukacyjnych, opiekuńczych, a także w planowaniu inwestycji infrastrukturalnych. W statystyce coraz częściej dane z oficjalnych źródeł, takich jak Zakład Ubezpieczeń Społecznych, są uzupełniane o te pochodzące od operatorów sieci komórkowych czy kart płatniczych.

Partner serwisu

Szkolenia

Akademia Newserii

Akademia Newserii to projekt, w ramach którego najlepsi polscy dziennikarze biznesowi, giełdowi oraz lifestylowi, a także szkoleniowcy z wieloletnim doświadczeniem dzielą się swoją wiedzą nt. pracy z mediami.

.gif)

|

| |

| |

|