Carbotura, Inc. Launches 'Waste to Circular Manufacturing' - A Groundbreaking Leap Beyond Recycling

CARBOTURA UNVEILS WASTE TO CIRCULAR MANUFACTURING™, A REVOLUTIONARY LEAP BEYOND RECYCLING, TRANSFORMING WASTE INTO HIGH-VALUE RAW MATERIALS WITH ZERO EMISSIONS.

NAPLES, FL, UNITED STATES, April 22, 2025 /EINPresswire.com/ -- Carbotura, Inc., based in Naples, Florida, proudly announces the launch of its revolutionary Waste to Circular Manufacturing™ (WtCM) platform—a transformative new industrial category that goes beyond traditional waste management, landfilling, and even recycling. With this bold step, Carbotura is establishing a new global standard for turning waste into perpetual value.Rather than simply managing waste or attempting to recycle it, Carbotura’s proprietary Pregenesis™ and Regenesis™ processes deconstruct waste at the molecular level and rebuild it into high-value raw materials, completing the circular economy in a way never before achieved.

"We don't manage waste. We end it. Waste is now a feedstock for high-value circular manufacturing," said Allen Witters, Chairman of Carbotura. "This isn't just disruption—it's the beginning of a new industrial era. Waste has officially left the waste industry."

Carbotura's model is already gaining global traction. The company has recently secured two long-term government contracts in the U.S. and abroad, each spanning 30 years and backed by guaranteed revenues and materials supply. These milestone contracts, each representing multi-billion-dollar value over their lifetimes, reflect growing institutional demand for scalable, zero-emissions infrastructure.

"At Carbotura, the time for incremental change is over. Waste to Circular Manufacturing isn't just a technological advancement, it's a paradigm shift," said Pelle Malmhagen, CEO of Carbotura. "Each modular facility is designed to process 400 tons of waste per day, achieving zero emissions and 100% material recovery. We are redefining waste as a renewable resource, empowering communities, and proving that circular economies aren't just possible, they're profitable, scalable, and already underway."

From Trash to Transformation: A New Industrial Category 'WtCM'

By converting all forms of municipal, commercial, and industrial waste into reusable elemental materials, Carbotura eliminates the need for landfills, incinerators, and complex recycling streams. Instead, recovered carbon, hydrogen, metals, and minerals are used to manufacture next-generation products—without emissions or secondary waste.

Carbotura's systems are modular, AI-integrated, and locally deployable—designed to serve regional communities while eliminating logistical inefficiencies and environmental harm. Each facility acts as a self-contained "Circular Materials Manufacturing" hub capable of processing hundreds of tons of raw waste daily with zero emissions and zero waste.

Closing the Circular Loop for Good

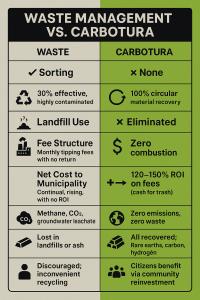

Traditional recycling systems are fragmented and economically inefficient. Carbotura removes complexity and increases value by fully closing the loop. This leap past recycling marks the emergence of an entirely new industrial vertical—merging energy, chemistry, AI, and infrastructure into a self-sustaining, circular ecosystem.

A Global Vision with Local Roots

From its headquarters in Naples, Florida, Carbotura is advancing a global rollout of Waste to Circular Manufacturing facilities with active projects underway in North America and the Middle East. Each facility is tailored to local waste streams and powered by an economic model that promotes regional participation and ownership. Each facility brings long-term economic benefits to its host region, including skilled manufacturing jobs, regional ownership models, and next-gen infrastructure.

"The age of landfills is over. The age of circular wealth has begun," Witters added. "We invite communities, leaders, and innovators to join us and be part of the regenerative industrial future."

About Carbotura, Inc.

Carbotura is a U.S.-based infrastructure company pioneering the world’s first Waste to Circular Manufacturing™ platform. Utilizing proprietary AI-driven processes, electromagnetic molecular systems, and modular design, Carbotura transforms waste into valuable materials to power the future of sustainable manufacturing.

Carbotura - Redefining Sustainability

Institutional and community leaders interested in collaboration or co-development are invited to contact Carbotura directly.

Tyler Wood

Carbotura Inc.

press|carbotura.com| |press|carbotura.com

Visit us on social media:

LinkedIn

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Made In The USA Announces Top ARTIST Awards, and an Evening TAG Art Auction next weekend

NewSky Security Expands into Cyber Security Private Investigations to Combat Sophisticated Botnet and VPN Threats

CTO G. Vimal Kumar of Cyber Privilege Honored for Advancing Cyber Forensics and Digital Evidence in India

Kalendarium

Więcej ważnych informacji

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Prawo

KE proponuje nowy Fundusz Konkurencyjności. Ma pobudzić inwestycje w strategiczne dla Europy technologie

W środę 16 lipca Komisja Europejska przedstawiła projekt budżetu na lata 2028–2034. Jedna z propozycji zakłada utworzenie Europejskiego Funduszu Konkurencyjności o wartości ponad 400 mld euro, który ma pobudzić inwestycje w technologie strategiczne dla jednolitego rynku. Wśród wspieranych obszarów znalazła się obronność i przestrzeń kosmiczna. Na ten cel ma trafić ponad 130 mld euro, pięciokrotnie więcej niż do tej pory.

Firma

Były prezes PGE: OZE potrzebuje wsparcia magazynów energii. To temat traktowany po macoszemu

Choć udział odnawialnych źródeł energii w miksie energetycznym Polski jest stosunkowo wysoki i rośnie, to ten przyrost jest chaotyczny i nierównomiernie rozłożony miedzy technologiami – wskazuje Forum Energii. Dodatkowo OZE potrzebują wsparcia magazynów energii, a zdaniem Wojciecha Dąbrowskiego, prezesa Fundacji SET, ten temat jest traktowany po macoszemu. Brak magazynów powoduje, że produkcja energii z OZE jest tymczasowo wyłączana, co oznacza marnowanie potencjału tych źródeł.

Infrastruktura

Wzrost wynagrodzeń ekip budowlanych najmocniej wpływa na koszty budowy domu. Zainteresowanie inwestorów mimo to nieznacznie wzrasta

Budowa metra kwadratowego domu w Polsce kosztuje od 5,55 do 6 tys. zł w zależności od województwa – wynika z najnowszych analiz firmy Sekocenbud. Najdrożej jest w Warszawie, gdzie cena za metr kwadratowy domu przekroczyła już 6,2 tys. zł. Na przyrosty kosztów budowy domu wpływają zarówno drożejące materiały budowlane, jak i wyższe wynagrodzenia pracowników. Inwestorzy nie rezygnują jednak z budowy domów jednorodzinnych, co ma związek m.in. z wciąż wysokimi cenami mieszkań czy też obniżką stóp procentowych.

Partner serwisu

Szkolenia

Akademia Newserii

Akademia Newserii to projekt, w ramach którego najlepsi polscy dziennikarze biznesowi, giełdowi oraz lifestylowi, a także szkoleniowcy z wieloletnim doświadczeniem dzielą się swoją wiedzą nt. pracy z mediami.

.gif)

|

| |

| |

|