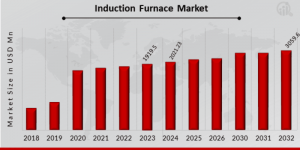

Induction Furnace Market to hit USD 3,059.6 Million by 2032, expanding at 5.32% CAGR | Wertli, FOMET, Electrotherm, ABP

Induction Furnace Market expands due to increased demand for metal melting, recycling, and energy-efficient solutions in industries.

Induction Furnace Market Overview:

The induction furnace market is a crucial component of the broader metal processing industry, specifically for steel and iron production. Induction furnaces use electromagnetic induction to heat metals for casting or melting, offering a cleaner, energy-efficient, and cost-effective alternative to traditional methods. Induction furnaces are increasingly used in manufacturing sectors such as automotive, construction, aerospace, and consumer goods, owing to their ability to precisely control the temperature, improve the quality of the product, and reduce waste. Over the past few years, the market has experienced significant growth, driven by technological advancements and increasing demand for high-quality metals and alloys.

Induction furnaces are particularly favored for their capacity to handle a wide range of metal types, including ferrous and non-ferrous metals. These furnaces operate by generating an electric current through an induction coil, creating a magnetic field that induces a current in the metal charge. This results in heating the metal to the desired temperature. With advantages such as faster melting rates, low emissions, and energy efficiency, induction furnaces have found applications in various industries, contributing to the overall expansion of the market.

Get Free Sample PDF Brochure: https://www.marketresearchfuture.com/sample_request/8251

Key Companies in the Induction Furnace Market include.

Ajax TOCCO Magnethermic Corporation

Electrotherm Limited

ABP Induction System

Inductotherm Corporation

FOMET

Otto Junker

Tenova SPA

Pioneer Furnaces Pvt.Ltd

Saint-Gobain

Duca Manufacturing

ZZ Industrial (shanghai) Co., Ltd.,

Topcast Engineering

Wertli AG

HarbisonWalker International

Marx GmbH & Co. KG

Market Trends Highlights:

Several key trends are currently shaping the induction furnace market. One of the most prominent is the ongoing trend toward automation and digitalization in manufacturing. Advanced control systems, machine learning algorithms, and automation technologies are being integrated into induction furnaces to enhance operational efficiency, improve safety, and reduce human error. Additionally, the increasing adoption of Industry 4.0 concepts, including the use of the Internet of Things (IoT), is enabling real-time monitoring and predictive maintenance, making induction furnaces more reliable and cost-effective.

Another trend gaining traction is the growing focus on sustainability. As industries worldwide face increasing pressure to reduce their carbon footprints, the adoption of environmentally friendly technologies has become paramount. Induction furnaces are known for their relatively lower energy consumption and fewer emissions compared to traditional methods, making them a more sustainable choice for metal processing. Moreover, the increasing emphasis on recycling scrap metal is pushing demand for induction furnaces since they are ideal for melting scrap and remelting metals for reuse.

Market Dynamics:

The induction furnace market is influenced by several key dynamics, both in terms of drivers and restraints, as well as opportunities for future growth.

Market Drivers:

Energy Efficiency and Cost-Effectiveness: Induction furnaces offer superior energy efficiency compared to conventional furnaces. As energy prices rise globally and industries seek to cut operational costs, the demand for energy-efficient solutions is increasing. Induction furnaces consume less energy to achieve the same output as other furnace types, making them more attractive to manufacturers who need to lower production costs while maintaining high-quality output.

Growth in End-User Industries: The rapid expansion of industries such as automotive, aerospace, and construction is driving the demand for high-quality metals and alloys. The increasing need for lightweight materials in automotive manufacturing, coupled with the ongoing demand for high-strength materials in construction, is creating a significant market for induction furnaces. These sectors rely on induction furnaces for melting and alloying metals to meet the specific demands of their applications.

Technological Advancements: Advances in induction furnace technology have led to the development of more efficient systems, including improved power electronics, enhanced control systems, and integration with IoT-based monitoring. These advancements help increase furnace productivity, reduce downtime, and lower operational costs, thereby expanding the adoption of induction furnaces in various industries.

Buy Now Premium Research Report: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=8251

Market Restraints:

High Initial Investment: One of the primary challenges facing the induction furnace market is the high initial cost of purchasing and installing these systems. Although they offer long-term operational savings, the upfront investment can be a barrier for small and medium-sized enterprises (SMEs) to adopt induction furnaces. This can limit the market’s growth potential in certain regions and industries where budget constraints are a concern.

Skilled Labor Requirement: Induction furnaces require specialized knowledge for their operation and maintenance. The complexity of the technology means that skilled operators are needed to ensure smooth functioning. There is a shortage of trained professionals in some regions, which may hinder the growth of the induction furnace market, especially in developing countries where training and education programs for such technologies are limited.

Market Segmentation:

The induction furnace market can be segmented based on several factors, including the type of furnace, application, and region.

By Type:

Coreless Induction Furnace: This is the most commonly used type of induction furnace and is used for melting a wide range of metals and alloys.

Channel Induction Furnace: These furnaces are used for high-capacity melting of metals and are generally preferred for steel production.

By Application:

Steel and Iron Industry: The steel and iron industries are the largest consumers of induction furnaces, as these furnaces are ideal for melting and alloying these metals.

Non-ferrous Metals Industry: Induction furnaces are also used for processing non-ferrous metals like aluminum, copper, and brass.

Automotive and Aerospace: These industries require high-quality metal alloys for manufacturing critical parts, which are produced using induction furnaces.

Browse In-depth Market Research Report: https://www.marketresearchfuture.com/reports/induction-furnace-market-8251

Future Trends:

Looking ahead, the induction furnace market is expected to witness robust growth, driven by a combination of technological advancements, industry expansion, and increasing demand for energy-efficient solutions. Future trends include:

Integration of AI and IoT: The integration of artificial intelligence (AI) and IoT into induction furnace operations will further optimize performance. AI-powered systems will enable predictive maintenance, real-time monitoring, and improved operational efficiencies, reducing downtime and energy consumption.

Shift Toward Sustainability: With increasing global focus on environmental regulations and carbon reduction, the future of the induction furnace market is aligned with sustainable manufacturing practices. Induction furnaces' energy efficiency and minimal environmental impact position them as a preferred choice in environmentally-conscious industries.

Increasing Automation: Automation in metal production is set to rise, with automated induction furnace systems enhancing productivity and minimizing human error. The future will likely see more fully automated induction furnace setups with integrated control systems, improving consistency and reducing labor costs.

More Related Reports:

Hvac Terminal Units Market: https://www.marketresearchfuture.com/reports/hvac-terminal-units-market-23236

Hybrid Valve Market: https://www.marketresearchfuture.com/reports/hybrid-valve-market-23291

Hydraulic Elevators Market: https://www.marketresearchfuture.com/reports/hydraulic-elevators-market-23309

Hydroponic Nutrients Market: https://www.marketresearchfuture.com/reports/hydroponic-nutrients-market-23221

In Line Process Viscometer Market: https://www.marketresearchfuture.com/reports/in-line-process-viscometer-market-23293

Industrial Aerators Market: https://www.marketresearchfuture.com/reports/industrial-aerators-market-23310

Industrial Brake Caliper Market: https://www.marketresearchfuture.com/reports/industrial-brake-caliper-market-23234

Dialogue with Three Chords and brooklynONE Productions Celebrate Pride Month with Night of Original Theatre

Business Solutions Marketing Group Unveils AI Video Marketing Program: Propelling Small Businesses to Google Page ONE

Eylsia, Rising Filipina Pop Artist, Explores the Promise and Challenges of AI in Music

Kalendarium

Więcej ważnych informacji

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Handel

Ze względu na różnice w cenach surowce wtórne przegrywają z pierwotnymi. To powoduje problemy branży recyklingowej

Rozporządzenie PPWR stawia ambitne cele w zakresie wykorzystania recyklatów w poszczególnych rodzajach opakowań. To będzie oznaczało wzrost popytu na materiały wtórne pochodzące z recyklingu. Obecnie problemy branży recyklingu mogą spowodować, że popyt będzie zaspokajany głównie przez import. Dziś do dobrowolnego wykorzystania recyklatów nie zachęcają przede wszystkim ceny – surowiec pierwotny można kupić taniej niż ten z recyklingu.

Przemysł spożywczy

Rośnie presja konkurencyjna na unijne rolnictwo. Bez rekompensat sytuacja rolników może się pogarszać

Rolnictwo i żywność, w tym rybołówstwo, są sektorami strategicznymi dla UE. System rolno-spożywczy, oparty na jednolitym rynku europejskim, wytwarza ponad 900 mld euro wartości dodanej. Jego konkurencyjność stoi jednak przed wieloma wyzwaniami – to przede wszystkim eksport z Ukrainy i niedługo także z krajów Mercosur, a także presja związana z oczekiwaniami konsumentów i Zielonym Ładem. Bez rekompensat rolnikom może być trudno tym wyzwaniom sprostać.

Transport

Infrastruktury ładowania elektryków przybywa w szybkim tempie. Inwestorzy jednak napotykają szereg barier

Liczba punktów ładowania samochodów elektrycznych wynosi dziś ok. 10 tys., a tempo wzrostu wynosi ok. 50 proc. r/r. Dynamika ta przez wiele miesięcy była wyższa niż wyniki samego rynku samochodów elektrycznych, na które w poprzednim roku wpływało zawieszenie rządowych dopłat do zakupu elektryka. Pierwszy kwartał br. zamknął się 22-proc. wzrostem liczby rejestracji w ujęciu rocznym, ale kwiecień przyniósł już wyraźne odbicie – o 100 proc.

Partner serwisu

Szkolenia

Akademia Newserii

Akademia Newserii to projekt, w ramach którego najlepsi polscy dziennikarze biznesowi, giełdowi oraz lifestylowi, a także szkoleniowcy z wieloletnim doświadczeniem dzielą się swoją wiedzą nt. pracy z mediami.

.gif)

|

| |

| |

|