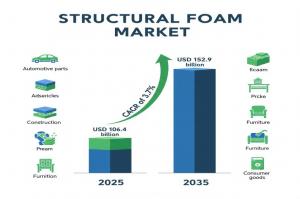

Structural Foam Market to Reach USD 152.9 Billion by 2035, Driven by Construction and Automotive Industry Demand

UK structural foam market grows at 3.5% CAGR, driven by transport, housing, and industrial use, with focus on durability, modularity, and efficient production.

NEWARK, DE, UNITED STATES, August 20, 2025 /EINPresswire.com/ -- The Structural Foam Market is set for significant growth, rising from USD 106.4 billion in 2025 to USD 152.9 billion by 2035, reflecting a CAGR of 3.7% over the forecast period. Between 2025 and 2030, the market will climb from USD 88.8 billion to USD 110.3 billion, representing a five-year gain of USD 21.5 billion or 24.2% cumulative growth.

Annual growth ranging between USD 3.2–3.9 billion underscores the market’s resilience and stability, driven by industries replacing traditional materials with structural foam in pursuit of lightweighting, rigidity, and cost-efficient design. As manufacturers in automotive, construction, and packaging prioritize efficiency, structural foam’s unique balance of strength and low material stress has positioned it as an indispensable solution.

Key Demand Drivers Across Industries

• Construction Sector Leadership: Accounting for 42–43% of total demand, the building and construction industry remains the largest end-user. Structural foam is increasingly used in insulation panels, lightweight walls, and civil infrastructure components that require high strength-to-weight performance.

• Automotive & Transportation Growth: Holding 35–40% of market share, the automotive sector leverages structural foam for seat bases, bumpers, interior panels, and HVAC systems. The rise of electric vehicles is further accelerating adoption in battery protection, modular interiors, and lightweight structural elements.

• Durable Packaging & Material Handling: With 8–10% market contribution, structural foam enables manufacturers to produce pallets, crates, and reusable industrial containers, aligning with logistics optimization goals.

• Electronics & Beyond: Applications in housings, switchgear, consumer goods, and medical equipment collectively account for 15% of the market, emphasizing the material’s versatility across product design.

Polypropylene: The Leading Raw Material

In 2025, polypropylene is expected to hold a 37.9% share of the market. Its low density, recyclability, moisture resistance, and cost-effectiveness make it the raw material of choice. Manufacturers in automotive and logistics are rapidly adopting polypropylene-based foam components for battery enclosures, interior parts, and reusable packaging systems.

As global industries advance sustainability commitments, polypropylene aligns perfectly by delivering process efficiency, recyclability, and integration flexibility in low-pressure foam molding.

Injection Molding: The Preferred Manufacturing Process

Injection molding is anticipated to secure 41.2% of market revenue in 2025, thanks to its efficiency in producing high-strength, thick-walled components with minimal material waste. Its ability to support complex geometries, dimensional stability, and reduced cycle times has cemented its role across high-volume manufacturing.

Enhanced by gas-assist technologies and automation, injection molding remains the backbone of production in automotive, packaging, and consumer goods, ensuring precision while lowering costs.

Automotive: The Dominant Application Segment

The automotive industry is expected to account for 39.6% of the market by 2025, reinforcing its dominance. Stricter global regulations on fuel efficiency and emissions are driving the demand for lightweight yet durable materials.

Structural foam components—ranging from seating structures to bumpers and under-hood applications—deliver strength, thermal resistance, and impact absorption. The rise of electric and hybrid vehicles has further amplified demand, particularly for battery protection, noise insulation, and modular body structures.

Market Challenges and Opportunities

While the market shows steady expansion, manufacturers face process consistency challenges. Variations in resin grade, foaming agents, and molding temperatures often result in inconsistent density and mechanical strength. These issues raise scrap rates, quality costs, and downstream assembly risks.

However, leading producers are addressing these challenges through:

• Custom Resin Blends: Tailored chemistries for flame retardancy, UV stability, and insulation.

• Tooling Alliances: Collaborations between suppliers and OEMs for precision molding and structural optimization.

• Local Compounding Facilities: Regional pre-mix sites reducing supply chain delays and improving consistency.

By adopting automation and closed-loop monitoring, manufacturers can significantly improve yield, uniformity, and customer confidence.

Regional Outlook: Growth Anchored in Asia and Europe

• China: Growing at a 5.0% CAGR, demand is spurred by automotive interiors, appliances, and modular furniture, supported by an expanding low-pressure molding infrastructure.

• India: At 4.6% CAGR, adoption is fueled by appliance housings, automotive parts, and affordable housing projects.

• Germany: With 4.2% growth, structural foam is increasingly used in industrial machinery, HVAC systems, and automotive components.

• France & UK: Recording 3.9% and 3.5% CAGR respectively, demand is led by packaging, consumer goods, and modular construction systems.

Competitive Landscape: Innovation and Sustainability at the Core

The market is anchored by Tier 1 leaders such as The Dow Chemical Company, SABIC, Evonik Industries, Diab International AB, and Armacell International S.A. These global players are investing heavily in polymer chemistry, composite formulations, and renewable energy-based production facilities.

For instance, on September 3, 2024, Evonik Industries announced that its Darmstadt facility now produces ROHACELL® structural foam exclusively with 100% renewable electricity, cutting CO₂ emissions by 3,400 metric tons annually.

Tier 2 and Tier 3 suppliers are equally active, focusing on niche industries, regional manufacturing partnerships, and application-specific solutions. Their agility and tailored services, from pilot foam trials to onsite technical support, are enabling widespread adoption across industries.

Request Structural Foam Market Draft Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-22998

For more on their methodology and market coverage, visit https://www.futuremarketinsights.com/about-us.

The Road Ahead

From construction insulation and EV battery protection to modular furniture and durable packaging, the Structural Foam Market is on track to expand steadily. For manufacturers, the next decade offers an opportunity to embrace lightweighting, material efficiency, and sustainability without sacrificing design flexibility or performance.

By overcoming process consistency challenges and investing in advanced molding technologies, manufacturers can unlock structural foam’s full potential—cementing its role as the material of the future in industrial design and production.

Related Insights from Future Market Insights (FMI)

Structural Adhesive Market- https://www.futuremarketinsights.com/reports/structural-adhesives-market

Structure Directing Agents Market - https://www.futuremarketinsights.com/reports/structure-directing-agents-market

Foam Food Container Market - https://www.futuremarketinsights.com/reports/foam-food-container-market

Foam Mesh Sleeves Market - https://www.futuremarketinsights.com/reports/foam-mesh-sleeves-market

Editor’s Note:

The Structural Foam Market is gaining traction as industries adopt lightweight, durable, and cost-efficient solutions. With rising demand across transportation, construction, and packaging, manufacturers are innovating for performance and sustainability. This outlook highlights key growth drivers and future opportunities shaping the market.

Rahul Singh

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Hydraulic Hose Market Demand Rising at a Stellar 5% CAGR to Reach USD 19.9 Billion by 2035: Fact.MR Report

Titanium Powder Market is Expected to Grow USD 6.8 Billion by 2035, Driven by Aerospace & Additive Manufacturing | FMI

Global Toner Pads Market Set to Reach USD 6.56 Billion by 2035, Fueled by Innovation & Consumer Trends. | FMI

Więcej ważnych informacji

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Polityka

UE przyspiesza inwestycje w obronność i bezpieczeństwo. Pomagają w tym nowe narzędzia finansowe i uproszczenia dla przemysłu obronnego

Unijne inwestycje w bezpieczeństwo i przemysł obronny nabierają tempa. Strategia Gotowość 2030 zakłada integrację krajowych przemysłów obronnych państw członkowskich oraz rozwój nowych technologii w armiach. Komisja Europejska proponuje też różne możliwości zwiększenia finansowania wydatków obronnych. – Unia Europejska postawiła na bezpieczeństwo nie tylko w wymiarze deklaracji, ale też konkretnych programów – podkreśla Michał Szczerba, europoseł z Platformy Obywatelskiej.

Handel

Inflacja w nadchodzących miesiącach będzie pozostawała w celu inflacyjnym. Pojawia się duża przestrzeń do obniżek stóp procentowych

Inflacja już znajduje się w paśmie dopuszczalnych odchyleń od celu inflacyjnego i wszystko wskazuje na to, że pozostanie w nim przez dłuższy czas. Rada Polityki Pieniężnej również ma tego świadomość. Dlatego w czasie najbliższych posiedzeń powinny się pojawić obniżki stóp procentowych. Zdaniem ekonomisty dr. Jarosława Janeckiego rozsądnym poziomem głównej stopy procentowej byłby poziom 3,5–4 proc., czyli można się spodziewać obniżek o 100–150 punktów bazowych.

Nauka

Pomiar dokładnej liczby ludności pozostaje dużym wyzwaniem. W erze migracji wymaga to nowych narzędzi i definicji

Dokładne i porównywalne dane na temat ludności są niezbędne m.in. do celów statystycznych i administracyjnych. Dlatego rośnie zapotrzebowanie na statystyki z zakresu demografii, migracji, starzenia się społeczeństwa oraz dane regionalne i lokalne. Państwa Unii Europejskiej odchodzą od „tradycyjnego” spisu przeprowadzanego co 10 lat w kierunku wykorzystania danych ze źródeł administracyjnych. Przyszłością jest wykorzystanie w pomiarze danych z mediów społecznościowych czy sieci komórkowych.

Partner serwisu

Szkolenia

Akademia Newserii

Akademia Newserii to projekt, w ramach którego najlepsi polscy dziennikarze biznesowi, giełdowi oraz lifestylowi, a także szkoleniowcy z wieloletnim doświadczeniem dzielą się swoją wiedzą nt. pracy z mediami.

.gif)