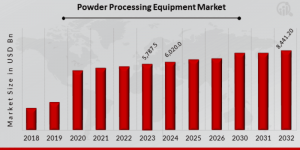

Powder Processing Equipment Market Projected to Reach Significant Growth with 4.2% CAGR by 2032 | Kemutec, Sollich UK

Powder Processing Equipment Market grows with demand for advanced materials in pharmaceuticals, chemicals, and manufacturing sectors.

Overview of the Powder Processing Equipment Market

The powder processing equipment market plays a crucial role in numerous industries such as chemicals, pharmaceuticals, food processing, minerals, and metallurgy, among others. This equipment is designed to process and manage powder particles for various applications such as mixing, grinding, classification, and agglomeration.

The increasing demand for high-performance powder processing solutions across various sectors, driven by evolving consumer preferences and technological advancements, has led to significant growth in the market. In this article, we explore the trends, dynamics, drivers, and outlook of the powder processing equipment market.

Get Free Sample PDF Brochure: https://www.marketresearchfuture.com/sample_request/9576

Key Companies in the Powder Processing Equipment market include

Hosokawa Micron Corporation

Baker Perkins Limited

Syntegon Technology GmbH

Hänsel Processing GmbH

Sollich UK Ltd

Dongsun Powder Processing Equipment Co. Ltd

Sanovo Technology Group

Powder Process-Solutions

Bepex International LLC

British Rema

Classifier Milling Systems

Powder Systems Corporation

Charles Ross & Son Company

Guilin Hongcheng Mining Equipment Manufacture Co. Ltd

Kemutec

Market Trends Highlights

One of the prominent trends in the powder processing equipment market is the growing demand for automation and smart technologies. Industrial automation systems such as robotics and artificial intelligence (AI) are increasingly being integrated into powder processing operations. These technologies allow for real-time monitoring, data collection, and predictive maintenance, ensuring greater efficiency and reducing human intervention. The integration of Industry 4.0 technologies helps improve overall operational efficiency, reduce downtime, and increase productivity, driving the adoption of advanced powder processing equipment.

Another notable trend is the rising preference for environmentally friendly and energy-efficient equipment. With increasing environmental concerns and regulatory pressures, companies are focusing on sustainable manufacturing processes. The demand for energy-efficient powder processing equipment is growing as businesses strive to meet stringent environmental regulations and reduce operational costs.

Market Drivers

Growth in End-User Industries: Industries such as pharmaceuticals, food processing, chemicals, and mining are driving the demand for powder processing equipment. For instance, the pharmaceutical industry requires precision in powder handling for active pharmaceutical ingredients (APIs) and excipients. Similarly, the food processing industry uses powders for making ingredients like milk powder, cocoa, and flavor additives. This growth in various end-user sectors contributes to the demand for more advanced powder processing solutions.

Technological Advancements: The continuous evolution of technology in powder processing equipment is a significant driver. With the development of more efficient mills, mixers, and classifiers, companies can process powders more quickly and with greater consistency. The integration of automated control systems and AI in powder processing equipment improves the overall quality and productivity of manufacturing processes.

Rising Demand for Customization: Powder processing equipment is increasingly required to accommodate custom solutions, especially in industries like pharmaceuticals and chemicals. Companies need equipment that can process materials with varying characteristics, such as different particle sizes or moisture contents. This growing need for customization is propelling the market, as manufacturers focus on providing flexible and adaptable powder processing systems.

Buy Now Premium Research Report: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=9576

Market Restraints

High Initial Investment: One of the primary challenges in the powder processing equipment market is the high initial investment required for purchasing and installing advanced processing systems. Smaller companies or startups may find it difficult to afford such equipment, which could limit market growth.

Complex Maintenance and Operational Costs: While powder processing equipment is efficient, it often requires regular maintenance to function optimally. Maintenance can be costly, especially if specialized parts or technicians are needed. Additionally, the operational costs associated with running large-scale powder processing equipment, including energy costs, can be a burden for some manufacturers.

Fluctuating Raw Material Costs: Powder processing equipment often deals with raw materials that can be affected by market fluctuations, which in turn affects the cost of processing. Price volatility of raw materials such as chemicals, minerals, or food products can lead to unpredictable manufacturing costs, making it difficult for companies to plan effectively.

Market Segmentation

The powder processing equipment market can be segmented based on the following factors:

Type of Equipment:

Mills: Used for grinding and reducing materials to fine powders. The most common types include ball mills, hammer mills, and impact mills.

Mixers: Equipment designed to blend powders and other ingredients to ensure uniformity. Types include ribbon blenders, V-blenders, and paddle mixers.

Classifiers: Machines used for separating powders based on particle size.

Dryers: Used for drying powder-based materials to remove moisture.

Agglomerators: Machines that form particles into larger, uniform granules.

End-User Industry:

Pharmaceuticals: For processing API powders and excipients.

Food & Beverages: For the production of milk powder, flavoring agents, and other powdered ingredients.

Chemicals: For processing raw chemical materials into fine powders.

Mining: For fine powder production from minerals.

Others: Such as cosmetics, ceramics, and plastics.

Browse In-depth Market Research Report: https://www.marketresearchfuture.com/reports/powder-processing-equipment-market-9576

Future Trends

As the powder processing equipment market continues to evolve, several trends are expected to shape its future:

Integration of Artificial Intelligence and IoT: The future of powder processing equipment will see more widespread use of artificial intelligence (AI) and the Internet of Things (IoT). These technologies will enable more efficient processing, real-time monitoring, and predictive maintenance, leading to reduced downtime and optimized production.

Sustainability and Green Manufacturing: Manufacturers are increasingly focusing on sustainability. Future trends will likely see more energy-efficient and eco-friendly powder processing equipment that reduces waste and minimizes environmental impact. Green manufacturing processes will become an essential part of market growth.

Customization and Automation: Demand for highly customized and automated powder processing systems will continue to rise. Companies will seek solutions that not only meet specific needs but also enhance the efficiency and flexibility of production lines.

More Related Reports:

Medical Facility Lighting System Market: https://www.marketresearchfuture.com/reports/medical-facility-lighting-system-market-23464

Manometers Market: https://www.marketresearchfuture.com/reports/manometers-market-23463

Mini Skid Steer Rental Market; https://www.marketresearchfuture.com/reports/mini-skid-steer-rental-market-23469

Multi Component Injection Moulding Technology Market: https://www.marketresearchfuture.com/reports/multi-component-injection-moulding-technology-market-23471

NDT Inspection Service Market: https://www.marketresearchfuture.com/reports/ndt-inspection-service-market-23473

Piston Ram Valves Market: https://www.marketresearchfuture.com/reports/piston-ram-valves-market-23478

Nylon Monofilament Market: https://www.marketresearchfuture.com/reports/nylon-monofilament-market-23476

Macxvideo AI V3.5 Now Available with Exclusive Mid-Year Bundle Offer

Rooting out plant diseases: Research suggests computers aren't ready to run our farms

MyRealProduct Cohort Mentors Over 35 Aspiring Data Professionals, Launches 8 AI Products

Kalendarium

Więcej ważnych informacji

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Prawo

KE proponuje nowy Fundusz Konkurencyjności. Ma pobudzić inwestycje w strategiczne dla Europy technologie

W środę 16 lipca Komisja Europejska przedstawiła projekt budżetu na lata 2028–2034. Jedna z propozycji zakłada utworzenie Europejskiego Funduszu Konkurencyjności o wartości ponad 400 mld euro, który ma pobudzić inwestycje w technologie strategiczne dla jednolitego rynku. Wśród wspieranych obszarów znalazła się obronność i przestrzeń kosmiczna. Na ten cel ma trafić ponad 130 mld euro, pięciokrotnie więcej niż do tej pory.

Firma

Były prezes PGE: OZE potrzebuje wsparcia magazynów energii. To temat traktowany po macoszemu

Choć udział odnawialnych źródeł energii w miksie energetycznym Polski jest stosunkowo wysoki i rośnie, to ten przyrost jest chaotyczny i nierównomiernie rozłożony miedzy technologiami – wskazuje Forum Energii. Dodatkowo OZE potrzebują wsparcia magazynów energii, a zdaniem Wojciecha Dąbrowskiego, prezesa Fundacji SET, ten temat jest traktowany po macoszemu. Brak magazynów powoduje, że produkcja energii z OZE jest tymczasowo wyłączana, co oznacza marnowanie potencjału tych źródeł.

Infrastruktura

Wzrost wynagrodzeń ekip budowlanych najmocniej wpływa na koszty budowy domu. Zainteresowanie inwestorów mimo to nieznacznie wzrasta

Budowa metra kwadratowego domu w Polsce kosztuje od 5,55 do 6 tys. zł w zależności od województwa – wynika z najnowszych analiz firmy Sekocenbud. Najdrożej jest w Warszawie, gdzie cena za metr kwadratowy domu przekroczyła już 6,2 tys. zł. Na przyrosty kosztów budowy domu wpływają zarówno drożejące materiały budowlane, jak i wyższe wynagrodzenia pracowników. Inwestorzy nie rezygnują jednak z budowy domów jednorodzinnych, co ma związek m.in. z wciąż wysokimi cenami mieszkań czy też obniżką stóp procentowych.

Partner serwisu

Szkolenia

Akademia Newserii

Akademia Newserii to projekt, w ramach którego najlepsi polscy dziennikarze biznesowi, giełdowi oraz lifestylowi, a także szkoleniowcy z wieloletnim doświadczeniem dzielą się swoją wiedzą nt. pracy z mediami.

.gif)

|

| |

| |

|