Smarter sensing: one chip for the wide vacuum range

GA, UNITED STATES, June 23, 2025 /EINPresswire.com/ -- Vacuum sensors are indispensable in cutting-edge fields ranging from semiconductor manufacturing to space exploration. Yet current technologies often trade measurement range for accuracy—or vice versa. In response, researchers have introduced a novel micro-scale vacuum sensor that bridges this divide. Built on a dual-mode weak-coupling resonator (WCR), the sensor switches between two sensing modes to deliver both ultra-high sensitivity and stable accuracy across a wide pressure range (0.3–100,000 Pa). By combining two typically separate capabilities into one compact micro-electro-mechanical systems (MEMS) device, this innovation not only boosts performance but also simplifies system design—potentially transforming how vacuum is monitored in critical applications.

Accurate vacuum sensing is vital in controlling environments where minute changes in pressure can make or break entire processes. Traditional Pirani sensors offer broad range but fall short in accuracy and gas-independence, while capacitance diaphragm gauges (CDGs) provide high precision but within limited spans. Hybrid sensors that combine these often require bulky, multi-chip setups. Meanwhile, emerging mode-localized resonant sensors show promise for sensitivity, but struggle to maintain performance over wide pressure ranges. These limitations have long challenged engineers working in semiconductors, aerospace, and scientific instrumentation. Due to these persistent hurdles, there is an urgent need to rethink vacuum sensor design from the ground up.

A research team from the Aerospace Information Research Institute at the Chinese Academy of Sciences has proposed a breakthrough in vacuum sensing. Their study published on May 21, 2025, in Microsystems & Nanoengineering, details a novel micro-electro-mechanical systems (MEMS)-based sensor that integrates mode-localization and traditional resonance mechanisms on a single chip. Designed to toggle between modes depending on pressure levels, the sensor provides high resolution and stability across a wide pressure range. This design not only improves measurement performance but also reduces sensor size and dependency on gas types—key for harsh environments.

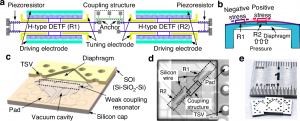

The innovation centers on a two-degree-of-freedom weak-coupling resonator (WCR) fabricated using MEMS bulk-silicon processing. Below 1,000 Pa, the sensor operates in mode-localized mode, where minute shifts in stiffness are detected through amplitude ratio changes, achieving a sensitivity of up to 30,000 ppm/Pa and a resolution of 0.1 Pa. When the pressure rises above 1,000 Pa, the sensor transitions to traditional resonance mode, where frequency becomes the output signal—delivering high linearity and a resolution of 2 Pa. Switching is controlled by tuning voltages that alter resonator stiffness and frequency alignment.

Structurally, the sensor includes two identical H-type double-ended tuning fork resonators anchored to a deformable diaphragm. This setup allows for differential sensing, reducing noise and common-mode stress. Housed in a vacuum-sealed cavity, the chip measures only 27.2 mm³—far smaller than existing commercial counterparts. Rigorous testing from −20 °C to 120 °C confirmed robust performance, low hysteresis, and minimal time drift. The sensor not only outperforms Pirani and CDG systems but also eliminates the need for multiple sensor integrations, streamlining both space and function in vacuum systems.

"Our sensor is designed to be both smart and adaptable," said Prof. Junbo Wang, the study's lead author. "By combining two sensing principles within a single MEMS platform, we've created a device that's compact, precise, and scalable. This dual-mode operation gives it a level of versatility that current vacuum sensors simply can't match. Whether it's for a chip fab or a space probe, this technology opens new possibilities for precision pressure monitoring."

The compact, high-performance design of this vacuum sensor positions it as a game-changing tool across multiple sectors. Its dual-mode capability allows seamless integration into semiconductor manufacturing lines, advanced vacuum chambers, and even planetary exploration equipment. The gas-independent architecture reduces calibration complexity, while its small size supports embedded deployment in miniaturized systems. As industries push for greater precision in smaller packages, this sensor offers a scalable solution that meets modern demands—delivering real-time, accurate vacuum monitoring from lab benches to Mars rovers.

References

DOI

10.1038/s41378-025-00937-z

Original Source URL

https://doi.org/10.1038/s41378-025-00937-z

Funding information

This work was supported in part by the National Key R&D Program of China under Grant 2023YFC2410600, in part by the National Natural Science Foundation of China under Grant 62301536 and Grant 62121003, in part by the Youth Innovation Promotion Association CAS Grant 2023134 and Grant 2022121, in part by the Instrument Research and Development of CAS under Grant PTYQ2024BJ0009, and in part by Science and Technology Program of Shandong Province under Grant 2023TSGC0211.

Lucy Wang

BioDesign Research

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Restaurantes en Polanco apuestan por cenas ligeras y equilibradas: Estas son las mejores opciones

leagend Unveils Customizable Lead‑Acid Charger ODM Solution to Enhance Gardening Tool Battery Lifespan and Efficiency

Dana L. Cox to Appear on Fintech.TV to Discuss How Business Acquisition Can Close the Wealth Gap for Women

Więcej ważnych informacji

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Ochrona środowiska

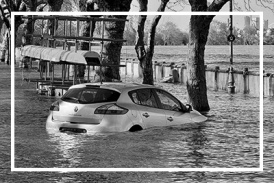

Kraje dotknięte powodzią z 2024 roku z dodatkowym wsparciem finansowym. Europosłowie wzywają do budowy w UE lepszego systemu reagowania na kryzysy

W lipcu Parlament Europejski przyjął wniosek o uruchomienie 280,7 mln euro z Funduszu Solidarności UE na wsparcie sześciu krajów dotkniętych niszczycielskimi powodziami w 2024 roku. Polska otrzyma z tego 76 mln euro, a środki mają zostać przeznaczone na naprawę infrastruktury czy miejsc dziedzictwa kulturowego. Nastroje polskich europosłów związane z funduszem są podzielone m.in. w kwestii tempa unijnej interwencji oraz związanej z nią biurokracji. Ich zdaniem w UE potrzebny jest lepszy system reagowania na sytuacje kryzysowe.

Handel

Nestlé w Polsce podsumowuje wpływ na krajową gospodarkę. Firma wygenerowała 0,6 proc. polskiego PKB [DEPESZA]

Działalność Nestlé w Polsce wsparła utrzymanie 45,2 tys. miejsc pracy i wygenerowała 20,1 mld zł wartości dodanej dla krajowej gospodarki. Firma przyczyniła się do zasilenia budżetu państwa kwotą 1,7 mld zł – wynika z „Raportu Wpływu Nestlé” w Polsce przygotowanego przez PwC na podstawie danych za 2023 rok.

Polityka

M. Kobosko: Surowce dziś rządzą światem i zdecydują o tym, kto wygra w XXI wieku. Zasoby Grenlandii w centrum zainteresowania

Duńska prezydencja w Radzie Unii Europejskiej rozpoczęła się 1 lipca pod hasłem „Silna Europa w zmieniającym się świecie”. Według zapowiedzi ma się ona skupiać m.in. na bezpieczeństwie militarnym i zielonej transformacji. Dla obu tych aspektów istotna jest kwestia niezależności w dostępie do surowców krytycznych. W tym kontekście coraz więcej mówi się o Grenlandii, autonomicznym terytorium zależnym Danii, bogatym w surowce naturalne i pierwiastki ziem rzadkich. Z tego właśnie powodu wyspa znalazła się w polu zainteresowania Donalda Trumpa.

Partner serwisu

Szkolenia

Akademia Newserii

Akademia Newserii to projekt, w ramach którego najlepsi polscy dziennikarze biznesowi, giełdowi oraz lifestylowi, a także szkoleniowcy z wieloletnim doświadczeniem dzielą się swoją wiedzą nt. pracy z mediami.

![Nestlé w Polsce podsumowuje wpływ na krajową gospodarkę. Firma wygenerowała 0,6 proc. polskiego PKB [DEPESZA]](https://www.newseria.pl/files/1097841585/fabryka-nesquik_1,w_85,r_png,_small.png)

.gif)

|

| |

| |

|