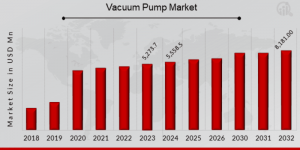

Vacuum Pump Market Set for 4.9% CAGR, Surpassing USD 8,181.00 Million by 2032 | Leybold, ULVAC, Atlas Copco AB, Ebara

Vacuum Pump Market grows with rising demand in semiconductors, pharmaceuticals, and industrial manufacturing applications.

Vacuum Pump Market An Overview

The vacuum pump market is integral to various industries that rely on the creation of a vacuum environment for their processes, including manufacturing, automotive, medical, chemical, and food processing. A vacuum pump is a mechanical device designed to remove gas molecules from a sealed volume, creating a partial or complete vacuum. This function is critical for applications like air conditioning, refrigeration, vacuum filtration, and semiconductor manufacturing. Vacuum pumps have evolved over time, adapting to diverse sectors with improved energy efficiency, automation capabilities, and specialized designs.

The global vacuum pump market has witnessed significant growth due to increased industrial activities and the demand for advanced manufacturing processes. As industries focus on automation and process optimization, vacuum pumps play a crucial role in maintaining the precision and quality of production systems. The market is expected to continue expanding with technological advancements and emerging applications, with notable growth in sectors such as electronics, healthcare, and automotive.

Get Free Sample PDF Brochure: https://www.marketresearchfuture.com/sample_request/11708

Key Companies in the Vacuum Pump Market include.

Atlas Copco AB

Pfeiffer Vacuum Technology AG

Ingersoll Rand

Agilent Technologies Inc.

ULVAC Inc.

Ebara Corporation

Leybold

Busch Vacuum Pumps and Systems

Shimadzu Corporation

Kashiyama Industries Ltd

KNF Neuberger GmbH

Gast Manufacturing Inc.

Market Trends Highlights

Several trends are shaping the future of the vacuum pump market. One significant trend is the growing demand for energy-efficient and eco-friendly vacuum pumps. With rising energy costs and heightened environmental concerns, industries are shifting towards pumps that offer reduced energy consumption while maintaining high performance. Manufacturers are increasingly focusing on creating pumps that are not only efficient but also compliant with global environmental standards, such as the use of sustainable materials and eco-friendly lubricants.

Another trend is the advancement of digital technologies and automation in vacuum pump systems. Vacuum pumps are now often integrated into smart systems that allow real-time monitoring and data analysis. This integration enables operators to optimize performance, predict maintenance needs, and reduce operational downtime, resulting in improved overall efficiency.

Market Drivers

Industrial Expansion: The rise in industrial production and automation in sectors like automotive, manufacturing, and semiconductor fabrication is driving the demand for vacuum pumps. As these industries increasingly adopt automated and precision-driven processes, vacuum pumps become vital in maintaining optimal production conditions.

Technological Advancements: Innovations in vacuum pump design, such as the development of dry vacuum pumps and energy-efficient models, are fueling market growth. Technological improvements make vacuum pumps more versatile, easier to maintain, and more cost-effective for businesses to implement.

Healthcare and Medical Applications: The healthcare sector's growth, especially in medical equipment manufacturing, is also driving the vacuum pump industry. Vacuum pumps are essential in laboratory environments, blood filtration, surgical operations, and respiratory equipment, further propelling demand in this segment.

Buy Now Premium Research Report: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=11708

Market Restraints

High Initial Investment: Despite technological advancements, vacuum pumps still represent a significant capital expenditure for industries, particularly small and medium-sized enterprises (SMEs). The high cost of purchasing and installing vacuum pumps can act as a barrier to entry for some companies, especially in developing markets.

Maintenance and Operational Costs: While vacuum pumps are essential for various processes, they also require regular maintenance and repairs to operate efficiently. The maintenance of vacuum pumps can be costly, especially in industries with stringent operational conditions. These costs can deter smaller companies from adopting advanced vacuum pump technologies.

Noise and Vibration Issues: Vacuum pumps, particularly larger models, can generate significant noise and vibration during operation. This can be a concern in environments where noise reduction is critical, such as in medical or laboratory settings. Manufacturers are working to address these issues, but they remain a challenge in certain applications.

Market Segmentation

The vacuum pump market can be segmented based on technology, application, and geography.

By Technology

Positive Displacement Vacuum Pumps: These pumps are the most common type and operate by trapping a fixed volume of gas, then forcing it out. They include rotary vane pumps, diaphragm pumps, and piston pumps. They are typically used in applications that require a high level of vacuum, such as in the chemical industry and vacuum packaging.

Momentum Transfer Vacuum Pumps: These pumps use a high-speed rotating impeller to impart momentum to gas molecules, effectively transferring the gas out of the system. Turbomolecular pumps are an example of momentum transfer pumps, widely used in semiconductor manufacturing and research applications.

Entrapment Pumps: These pumps work by capturing gas molecules in a material or surface. The most common type of entrapment pump is the cryopump, which operates by freezing gas molecules. They are commonly used in ultra-high vacuum systems.

By Application

Semiconductor and Electronics Manufacturing: Vacuum pumps are essential in the production of semiconductors and microelectronics. They are used in processes such as thin-film deposition, etching, and testing of integrated circuits, where high vacuum environments are critical.

Automotive: In the automotive sector, vacuum pumps are used in brake assist systems, fuel systems, and HVAC systems. With the rise of electric vehicles (EVs), there has been an increased demand for high-efficiency vacuum pumps in these applications.

Medical and Healthcare: Vacuum pumps are used extensively in medical equipment like respirators, suction devices, and laboratory equipment. The demand for vacuum pumps in healthcare is expected to grow as healthcare infrastructure continues to expand globally.

Chemical and Pharmaceutical: In these industries, vacuum pumps are used for distillation, filtration, and drying processes. They are crucial for maintaining the desired pressure and purity levels during chemical reactions and pharmaceutical manufacturing.

Food and Beverage: Vacuum pumps are used in the food packaging process, such as vacuum sealing to extend shelf life. They are also used in food processing systems that require low pressure environments.

Browse In-depth Market Research Report: https://www.marketresearchfuture.com/reports/vacuum-pumps-market-11708

Future Trends

Looking forward, the vacuum pump market is poised for substantial growth. The focus on energy efficiency and sustainability will likely drive future product innovations, with manufacturers investing in the development of pumps that minimize energy use and reduce their environmental impact. Additionally, the integration of advanced control systems and Internet of Things (IoT) technology will enable smarter, more automated vacuum systems. This will allow businesses to monitor pump performance remotely and optimize operations in real-time.

As emerging economies continue to industrialize and technological advancements continue, the vacuum pump market is expected to see heightened demand in a range of industries. The future will likely witness increased demand for custom-designed vacuum pumps tailored to specific industrial needs, further fueling market expansion.

More Related Reports:

Valve Driver Market: https://www.marketresearchfuture.com/reports/valve-driver-market-23542

Valves And Actuators Market: https://www.marketresearchfuture.com/reports/valves-actuators-market-23545

Vapor Blasting Equipment Market: https://www.marketresearchfuture.com/reports/vapor-blasting-equipment-market-23567

Wear Resistant Steel Plate Market: https://www.marketresearchfuture.com/reports/wear-resistant-steel-plate-market-23580

Woodworking Tool Market: https://www.marketresearchfuture.com/reports/woodworking-tool-market-23582

Power Stacker Market: https://www.marketresearchfuture.com/reports/power-stacker-market-23598

Powered Lawn Mower Market: https://www.marketresearchfuture.com/reports/powered-lawn-mower-market-23599

Levin & Perconti Secures $4.975M Settlement for Septic Shock That Lead to Patient's Death

Trident Wealth Partners Expands National Reach with Virtual Financial Advisory Services

Metro Building and Remodeling Group Rebrands as Metro Design Build Group

Kalendarium

Więcej ważnych informacji

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Jedynka Newserii

Prawo

KE proponuje nowy Fundusz Konkurencyjności. Ma pobudzić inwestycje w strategiczne dla Europy technologie

W środę 16 lipca Komisja Europejska przedstawiła projekt budżetu na lata 2028–2034. Jedna z propozycji zakłada utworzenie Europejskiego Funduszu Konkurencyjności o wartości ponad 400 mld euro, który ma pobudzić inwestycje w technologie strategiczne dla jednolitego rynku. Wśród wspieranych obszarów znalazła się obronność i przestrzeń kosmiczna. Na ten cel ma trafić ponad 130 mld euro, pięciokrotnie więcej niż do tej pory.

Firma

Były prezes PGE: OZE potrzebuje wsparcia magazynów energii. To temat traktowany po macoszemu

Choć udział odnawialnych źródeł energii w miksie energetycznym Polski jest stosunkowo wysoki i rośnie, to ten przyrost jest chaotyczny i nierównomiernie rozłożony miedzy technologiami – wskazuje Forum Energii. Dodatkowo OZE potrzebują wsparcia magazynów energii, a zdaniem Wojciecha Dąbrowskiego, prezesa Fundacji SET, ten temat jest traktowany po macoszemu. Brak magazynów powoduje, że produkcja energii z OZE jest tymczasowo wyłączana, co oznacza marnowanie potencjału tych źródeł.

Infrastruktura

Wzrost wynagrodzeń ekip budowlanych najmocniej wpływa na koszty budowy domu. Zainteresowanie inwestorów mimo to nieznacznie wzrasta

Budowa metra kwadratowego domu w Polsce kosztuje od 5,55 do 6 tys. zł w zależności od województwa – wynika z najnowszych analiz firmy Sekocenbud. Najdrożej jest w Warszawie, gdzie cena za metr kwadratowy domu przekroczyła już 6,2 tys. zł. Na przyrosty kosztów budowy domu wpływają zarówno drożejące materiały budowlane, jak i wyższe wynagrodzenia pracowników. Inwestorzy nie rezygnują jednak z budowy domów jednorodzinnych, co ma związek m.in. z wciąż wysokimi cenami mieszkań czy też obniżką stóp procentowych.

Partner serwisu

Szkolenia

Akademia Newserii

Akademia Newserii to projekt, w ramach którego najlepsi polscy dziennikarze biznesowi, giełdowi oraz lifestylowi, a także szkoleniowcy z wieloletnim doświadczeniem dzielą się swoją wiedzą nt. pracy z mediami.

.gif)

|

| |

| |

|